Make The Most Of Value: Aftermarket Construction Parts Basics

Wiki Article

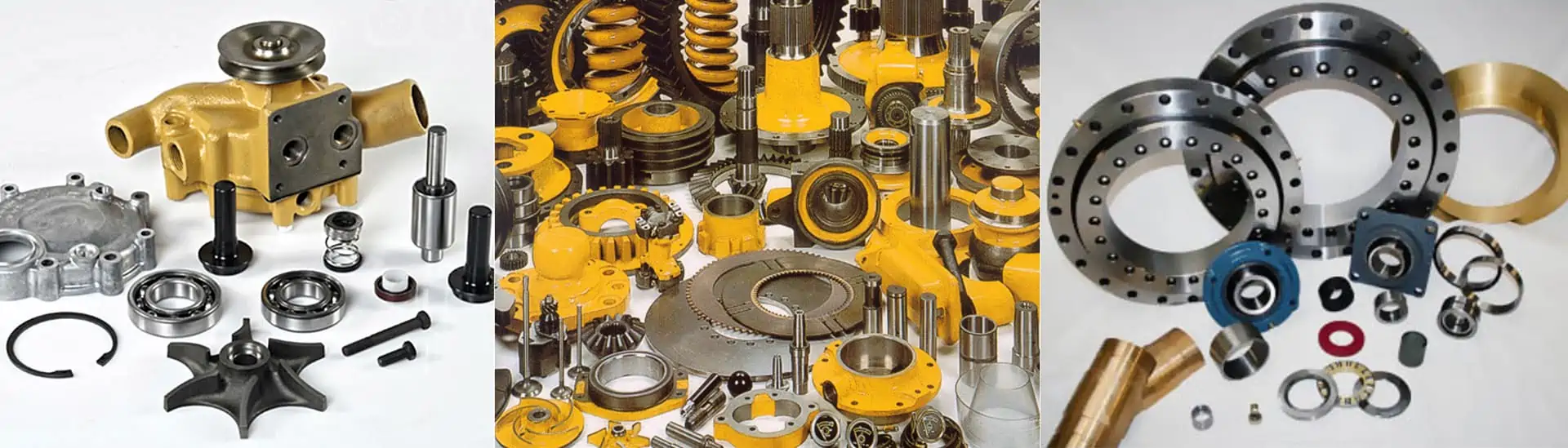

Enhance Your Heavy Equipment With Quality Aftermarket Building Components

Enhancing hefty equipment with top quality aftermarket building and construction parts can significantly impact the performance and durability of your devices. From enhanced efficiency to economical options, aftermarket building and construction components supply an array of benefits that provide to the varied requirements of heavy machinery operators.Benefits of Aftermarket Construction Components

Enhancing hefty equipment with aftermarket construction components can considerably improve efficiency and longevity. Aftermarket components are typically designed with updated materials and modern technologies, which can result in equipment that can endure extra extensive operating problems.Additionally, aftermarket construction parts can offer expense financial savings compared to acquiring original tools manufacturer (OEM) components. While OEM parts are usually more costly as a result of brand acknowledgment and exclusivity, aftermarket options supply an even more budget-friendly choice without compromising on high quality. This cost-effectiveness can be specifically beneficial for business aiming to optimize their functional expenditures without sacrificing the performance of their hefty equipment.

Factors to Take Into Consideration When Selecting Components

When selecting building parts for heavy machinery, it is necessary to carefully consider various elements to guarantee ideal performance and compatibility. Choosing for high-grade aftermarket building and construction components can significantly affect the general performance and durability of the machinery.

Another element to take into account is compatibility. Guaranteeing that the construction parts work with the specific make and version of the equipment is crucial to prevent any type of operational issues or damages. This consists of validating the dimensions, specs, and any additional needs for smooth combination.

Additionally, considering the cost-effectiveness of the components is necessary. While high quality ought to not be compromised, picking aftermarket components that provide a good equilibrium between quality and price can assist in optimizing the value of the financial investment.

Last but not least, accessibility and customer assistance ought to also be taken into consideration. Go with construction components that are readily offered and backed by outstanding consumer support to address any kind of worries or inquiries immediately. By thoroughly reviewing these elements, you can make enlightened decisions when picking aftermarket building components for your heavy equipment.

Installation Tips for Aftermarket Parts

To ensure a seamless and efficient installment procedure for aftermarket building parts on heavy machinery, meticulous focus to information and adherence to maker standards are critical. Before beginning the installment, it is critical to extensively check the aftermarket parts to confirm that they match the requirements of the initial parts and are totally free from any defects. In addition, arranging the workplace and making certain that the needed tools are conveniently offered can assist streamline the installment process.Following the supplier's setup instructions is important to assure proper fit and capability of the aftermarket components. Any inconsistency from these guidelines can lead to subpar efficiency or even possible safety and security hazards. It is additionally recommended to record the setup procedure, including any kind of adjustments made or obstacles experienced, for future referral.

Finally, performing a final examination after the installation is full can help determine any kind of problems or mistakes that may have been ignored - aftermarket construction parts. Testing the machinery to make certain that the aftermarket parts are working appropriately is an important last action in the setup procedure

Upkeep Guidelines for Upgraded Machinery

Regularly scheduled maintenance checks are important to guarantee that all aftermarket parts are functioning correctly. This includes inspecting components for wear and tear, oiling relocating components, and changing filters as required.In addition to routine maintenance, operators need to additionally focus on any kind of uncommon audios, resonances, or performance issues that may arise. Addressing these concerns without delay can stop additional damage to the machinery and its aftermarket components. Keeping comprehensive records of upkeep activities, repair work, and part substitutes can assist track the overall health of the updated machinery and identify any kind of persisting problems.

Furthermore, correct storage space and cleaning treatments must be followed to shield the machinery from environmental aspects that might accelerate use on aftermarket parts (aftermarket construction parts). By adhering to these maintenance standards carefully, operators can maximize the advantages of their upgraded equipment and ensure its ongoing reliability at work site

Cost-efficient Upgrades for Heavy Equipment

Executing strategic upgrades can substantially enhance the efficiency and efficiency of heavy equipment while maintaining cost-effectiveness. When taking into consideration affordable upgrades for hefty machinery, it is necessary to prioritize enhancements that supply the most considerable effect on efficiency without damaging the budget. One affordable upgrade is the installment of advanced telematics systems. These systems supply real-time information on equipment usage, gas intake, and maintenance requirements, permitting for proactive decision-making and decreasing downtime.An additional cost-effective upgrade check over here is the integration of GPS technology, which can enhance path planning, boost fuel effectiveness, and enhance general task website efficiency. Updating to even more long lasting tires or tracks can additionally be a sensible financial investment, as they can boost traction, decrease deterioration, and eventually prolong the life expectancy of the machinery. Additionally, retrofitting older machinery with energy-efficient components, such as LED lights or boosted hydraulic systems, can bring about lasting price financial savings with decreased energy consumption and upkeep expenditures. By meticulously picking and carrying out these economical upgrades, heavy machinery drivers can make best use of efficiency and effectiveness while staying within budget restraints.

Conclusion

Finally, aftermarket building parts use various advantages for improving hefty machinery. By meticulously thinking about factors such as compatibility and high quality, selecting the ideal parts can enhance efficiency and prolong the view publisher site life-span of equipment. their explanation Correct installation and routine upkeep are vital for ensuring ideal capability. In general, cost-efficient upgrades with aftermarket parts can result in raised efficiency and efficiency in building and construction operations.Enhancing heavy machinery with high quality aftermarket building components can dramatically impact the performance and durability of your devices.Enhancing hefty equipment with aftermarket building and construction components can significantly improve performance and durability.Moreover, aftermarket building components can supply price financial savings contrasted to acquiring initial tools manufacturer (OEM) parts.To ensure a seamless and efficient installation process for aftermarket construction parts on heavy equipment, thorough focus to information and adherence to supplier standards are vital. Prior to beginning the setup, it is essential to completely examine the aftermarket parts to validate that they match the requirements of the initial parts and are totally free from any defects.

Report this wiki page